GY-DG-80 Eco-Friendly Solution to Biodegradation

GY-DG-80 is a polymer containing high polymers of polycaprolactone (PCL) as well as long-chain and natural polysaccharides. Ultraviolet and oxidation will rapidly lead to a chain scission of polymers, causing the plastic to break into smaller pieces. After that, the polysaccharides in GY-DG-80 which is with high bonding strength will integrate into the plastic material and further induce a huge amount of bacteria to decompose the plastic. The plastic in the end will be decomposed into calcium oxide, water and carbon dioxide via biodegradation.

GY-DG-80, eco-friendly and biodegradable granules, can be used or processed with ABS, PS, traditional and general plastics including polyolefins to produce biodegradable products, which results in a broad applied field such as agriculture, industry, daily necessities, etc.

Description

Intro

Environmental issues have become market trends and even turn out to be a part of the factors that increase the product value. Hence, a huge number of international labels show their initiative on using, producing and selling products that are composed of bioplastics. Poly lactic acid (PLA) is an eco-friendly material that people currently pay much attention to. However, PLA is with a short period of storage and high price, and features weak oil/heat resistant properties; additionally, it cannot be recycled, mixed with other general plastics or be processed easily and efficiently. Due to the flaws, PLA can still not be used largely and broadly as yet.

GO YEN CHEMICAL INDUSTRIAL CO., LTD. (GYC GROUP) is currently the largest manufacturer of functional additives in Asia where two of our factories are built. As for a long period of time we put our efforts on high-end, eco-friendly and innovative research and development to improve the existing flaws of biodegradable materials on the present market in order to develop materials that can be processed efficiently and for mass production, we are able to provide a total solution to the worldwide processing or producing issues of biodegradable materials.

Decomposition mechanisms:

GY-DG-80 is a polymer containing high polymers of polycaprolactone (PCL) as well as long-chain and natural polysaccharides. Ultraviolet and oxidation will rapidly lead to a chain scission of polymers, causing the plastic to break into smaller pieces. After that, the polysaccharides in GY-DG-80 which is with high bonding strength will integrate into the plastic material and further induce a huge amount of bacteria to decompose the plastic. The plastic in the end will be decomposed into calcium oxide, water and carbon dioxide via biodegradation.

GY-DG-80, eco-friendly and biodegradable granules, can be used or processed with ABS, PS, traditional and general plastics including polyolefins to produce biodegradable products, which results in a broad applied field such as agriculture, industry, daily necessities, etc.

Properties

| GRADE | GY-DG-80 |

| Appearance | Granule |

| Color | Pear white |

| Moisture content | ≦0.1% |

| Compound performance | Excellent |

| Melting point | 160-180℃ |

| Odor | Odor free |

Features/Advantages

- High decomposition efficiency

- Environmental conditions such as soil, moisture, sunlight (ultraviolet), heat, bacteria, oxygen in the air will improve the decomposition efficiency

- Great compatibility with plastics that can be processed with polyolefins or engineering plastics

- Ease of storage

- High processability with plastics

- Will decompose naturally after buried and will lessen the quantity of trash

- Can be used as a replacement of traditional plastic or PLA

- Can be used in disposable plastic bags or other related products

Applications

- General plastics including polyolefins: PP, PE, HDPE, LDPE, LLDPE, EVA, PEVA, TPO, etc.

- Engineering plastics: ABS, PS, etc.

- Disposable plastic bags or other related products

- Agricultural uses: agricultural film, thin film, cup for growing seedlings, fruit foam mesh wrap, etc.

- Industrial uses: packing material, bottle, can, bandage, etc.

- Containers for food, drink, lotion (shampoo, liquid soap), etc.

- Daily necessities: packing material, garbage bag, shopping bag, umbrella, raincoat, shower liner, etc.

- Housewares: glove, apron, dining table cloth, clothes hanger, etc.

- Catering uses: plate, spoon, fork, straw, lunch box, disposable cup, cup lid, etc.

- Stationary: pen, folder, file clip, slipcase, etc.

- Any eco-friendly and biodegradable applications

Adding Rate

Recommended adding rate: 30%-50%

The adding rate is regarded as general guideline which can be adjusted according to type of material, required performances, and environmental conditions where plastics are to be buried.

The actual decomposition times vary depending on type of material, temperature, humidity, sunlight, and other environmental and climatic factors.

Decomposition Efficiency

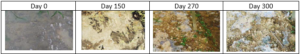

Formula: GY-DG-80*50% with PE*50%

Product: PE packing material with 20µm thickness

Conditions: temperature range 28-33℃

Evaluate and observe the changing of the buried packing material on day 0, day 150, and day 300.

Result:

Decomposition efficiency vary depending on temperature, humidity, sunlight, microbes, and other environmental and climatic factors.According to the burying test, the packing material is found to be decomposed 80% after 300 days.

Packing

25KG/bag

Storage

Store in a cool, dry, and well-ventilated place. Avoid direct sunlight.