GOYENCHEM-E650 Low-Carbon and Eco-Friendly Water Stain Resistant

In order to meet the demand of low carbon and energy saving requirements of the century, GYC Group dedicating to developing the eco-friendly products.

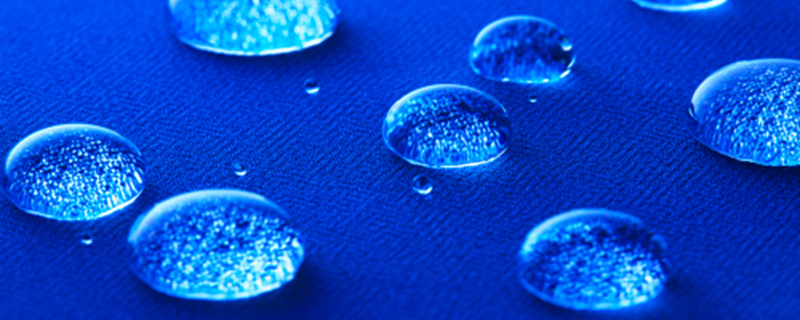

GOYENCHEM-E650 can be used for different sorts of fabric finishing, including natural fabrics, synthetic fabrics and blended fabrics products, etc. Using special technology of eco-friendly low carbon combination, GOYENCHEM-E650 provides high water & oil repellency to the fabrics.

Textiles treated with GOYENCHEM-E650 will provide a soft touch and feeling. GOYENCHEM-E650 obtains a well reputation and increases the product values. It is now a designated product of a number of textile producers in Europe, Japan, Korea and U.S.A.

Description

Intro

In order to meet the demand of low carbon and energy saving requirements of the century, GYC Group dedicating to developing the eco-friendly products.

GOYENCHEM-E650 can be used for different sorts of fabric finishing, including natural fabrics, synthetic fabrics and blended fabrics products, etc. Using special technology of eco-friendly low carbon combination, GOYENCHEM-E650 provides high water & oil repellency to the fabrics.

Textiles treated with GOYENCHEM-E650 will provide a soft touch and feeling. GOYENCHEM-E650 obtains a well reputation and increases the product values. It is now a designated product of a number of textile producers in Europe, Japan, Korea and U.S.A.

Properties

| GRADE | GOYENCHEM-E650 |

| Appearance | Milky liquid |

| pH value | Acid |

| Ion tape | Weak cation |

| Specific gravity | 1.1(20˚℃) |

| Solubility | 100% for H2O |

Features/Benefits

- The evolution technology of eco-friendly product of low carbon method, which has already appointed by the renown companies as standard formula

- PFOA or PFCAs free under the production processing

- Alkylphenol free

- Offers perfect water & oil resistant property to textiles

- Provides outstanding soft handling and feeling

- Provides excellent permeability and moistening ability to fabrics with bad moistening or high-speed processing

- Can be widely used for high and low temperature production process

- Adding dyeing additives or proceeding agents during pre-processing does not affect the properties of water & oil repellency of GOYENCHEM-E650

- Does not affect original coloring, friction fastening, washing fastening, dyeing, and printing, etc.

- To increase function of product for textile products through nanometer waterproof

- Excellent oil resistant and IPA resistant

Adding Rate

The adding rate is to be regarded as general guideline which can be adjusted according to the type of fabric and the expected effect.

The recommended adding rate is shown as follows:

| Dilution percentage | |

| 20~40g | 1L |

The recommended adding rate provided by GO YEN Technical section is for reference only. The dose should be adjusted in accordance with different formulas, designs and purposes.

| Pad | 1 dip 1nip(3kg/ cm2) | Time |

| Dry | 100 ~ 120℃ | 1~3 Min |

| Cure | 150 ~ 170℃ | 1~3 Min |

Example:

| Processing method, Testing condition: Pad method 1dip 1nip pressure=3kg/ cm2 | ||

| Testing fabrics | Material | Pick-up rate |

| PET (100%) Taffeta | Dyed fabric | 89% |

| Nylon (100%) Taffeta | Dyed, fixing dyed fabrics | 32% |

| PET/C(50/50) | Woven dyed, fixing dyed fabric | 61% |

| Test standard: Water resistant: ISO 4920 (Spray) | ||

Applications

- Can be used with other charged prevent agent, softening agent, permeating agent. Please confirm its compatibility and water & oil resistant. Mix the agent first and dilute with water between 30% and 50%

- Suitable for all kinds of acrylic resins, rubber resin coating processing, adhesion and label processing because of good adhesive of processing surface

- Can be applied to paper making with special purpose, wood fiber, and cellulose waterproof application

Note

- When diluted, use water below 40℃ and the processing liquid temperature should not higher than 40℃.

- pH scale of processing liquor should be adjusted less than 7. The stability and water/oil repellent effect might be affected due to strong acidity or strong basicity.

- Finish the water/oil repellent agent as soon as possible once it is diluted and prevent reusing.

- Pre-processing fabric should wash clearly and avoid impurities, hydrophilic substances or anionic residues.

- Wear suitable equipment during operation and avoid contact with body directly.

- Do not inhale vapor and mixture during processing.

- Do not mix with other material when pouring out GOYENCHEM-E650 from the container.

Packing

120 KG or 200 KG/Drum

Storage

Store in a cool, dry, and well-ventilated place in the temperature between 5 and 40℃.

Seal tightly after use and avoid sunlight.