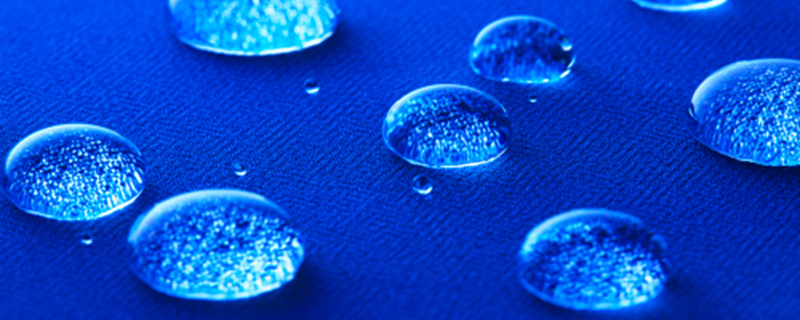

GOYENCHEM-E630 Eco-Friendly Low-carbon Water & Oil Repellent

GOYENCHEM-E630 can be applied to different sorts of fabric finishing, including natural fabrics, synthetic fabrics, and blended fabrics. GOYENCHEM-E630 provides your fabric with exceptional water & oil repellency, using the special technology of eco-friendly low carbon combination.

Description

Intro

GO YEN CHEMICAL INDUSTRIAL CO., LTD. (GYC GROUP) is a leading manufacturer of specialty chemicals in Asia. We devote ourselves to supplying products and solutions to our customers worldwide to satisfy and expand the market needs.

GOYENCHEM-E630 can be applied to different sorts of fabric finishing, including natural fabrics, synthetic fabrics, and blended fabrics. GOYENCHEM-E630 provides your fabric with exceptional water & oil repellency, using the special technology of eco-friendly low carbon combination.

Textiles treated with GOYENCHEM-E630 feature a soft touching sensation. GOYENCHEM-E630 earns reputation and is designated by many textile producers in Europe, Japan, Korea, and the United States.

Properties

| GRADE | GOYENCHEM-E630 |

| Physical State | Milky liquid |

| PH value | Acid |

| Ion type | Weak cation |

| Specific gravity | 1.1(20℃) |

| Solubility | 100% for H2O |

Features/Advantages

- Consists of no PFOA or PFCAs ingredients under the production process

- Exceptional water and oil repellency

- No Alkylphenol.

- Provides outstanding soft handling sensation

- Excellent permeability and moistening ability to fabrics with bad moistening or high-speed processing

- Applicable in high and low-temperature production process via nanometer technique

- Adding dyeing additives or proceeding agents during pre-processing does not affect the properties of water & oil repellency

- No effect on original coloring, friction fastening, wash fastening, dyeing, printing, etc.

- Increases added value of products

- Excellent Oil and IPA resistant

Applications

- Can be applied to natural fabrics & synthetic fabrics

- Suitable for all kinds of acrylic resins, rubber resin coating process, adhesion, and label processing

- Papermaking, wood fiber, and cellulose

Dosage

Recommended adding rate: 20-40g in 1L

The dosage level is to be regarded as a general guideline that can be adjusted according to type of material and the expected effect.

Packing

120KG/drum; 200KG/drum